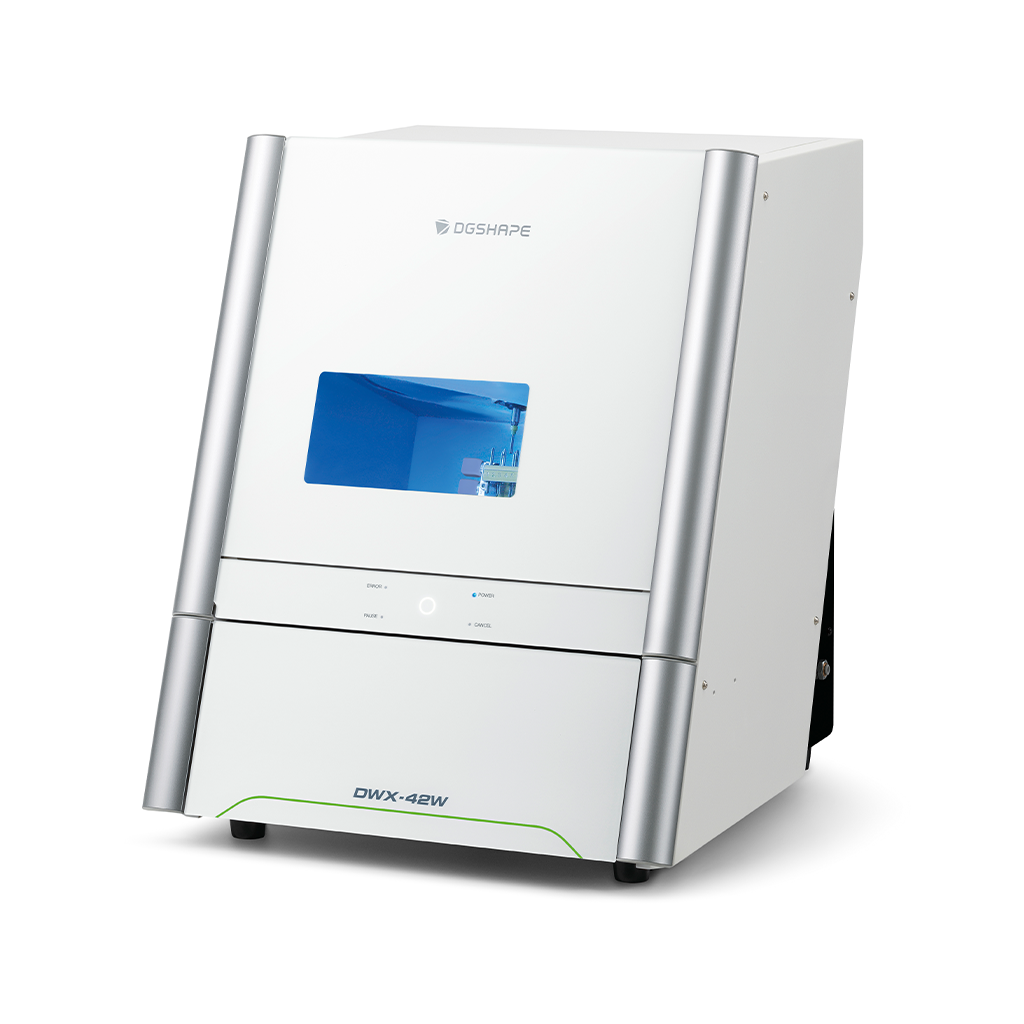

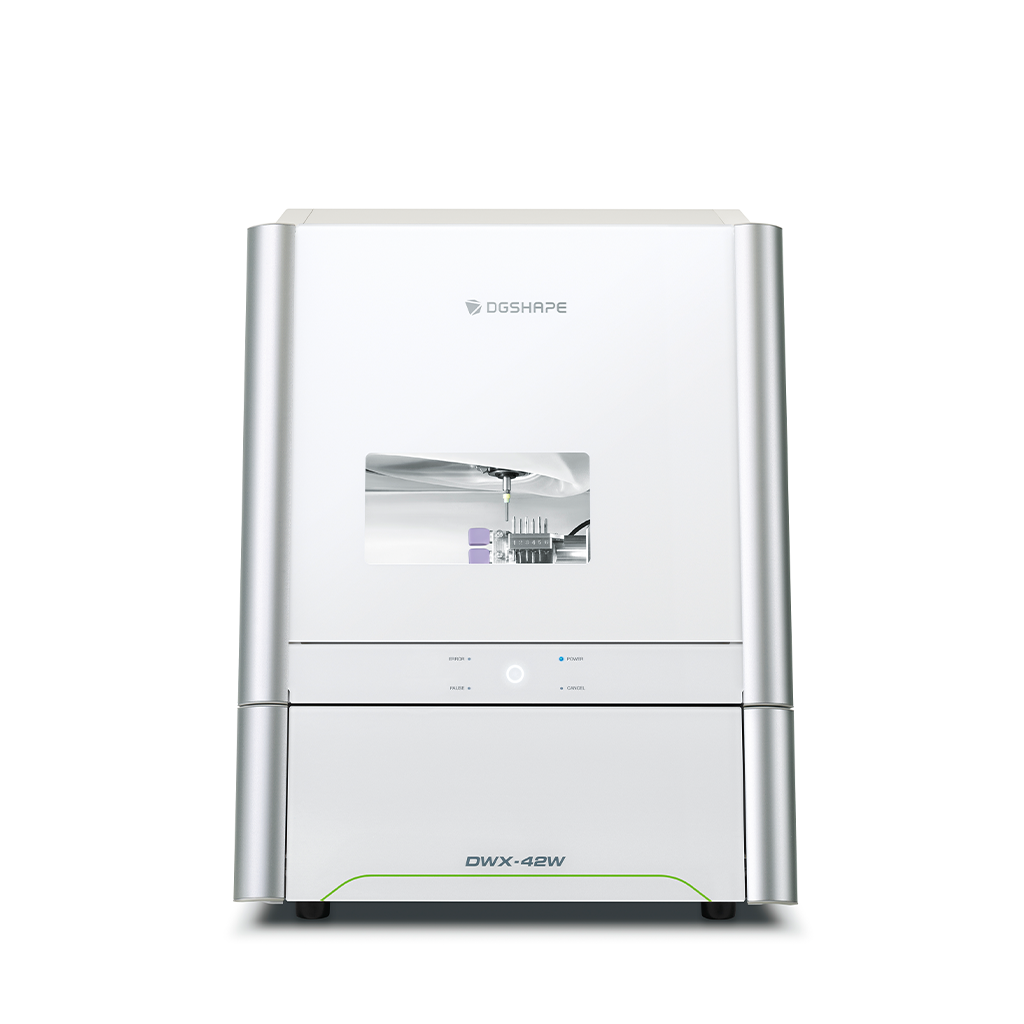

DWX-42W Plus

The DGSHAPE DWX-42W Plus enables the grinding of popular materials such as glass-ceramic and composite with high precision and accuracy.

- High-speed production with the unique DGSHAPE spindle

- The extended automatic six-station tool changer enables uninterrupted grinding.

- LAN capability enables integration into networks and communication with other hardware.

- The VPanel user interface allows easy monitoring of grinding tasks and tools.

Price on request

RRP 29.490,00€

Description

Problem-free in All laboratory and clinical workflows can be integrated

Laboratories

- Expand production with a stand-alone wet grinding capability suitable for materials such as glass ceramic and composite resin.

- Enjoy the same flexibility and high-quality performance you've come to expect from DGSHAPE dry grinders in wet grinding configurations, thanks to the open architecture.

- Expand your offer with on-demand production of highly esthetic dental restorations.

Clinics

- Offer your patients highly accurate same-day dental restorations - fabricated on a user-friendly machine and in a simplified workflow.

- The open architecture allows seamless integration with existing scanning devices.

- Reliable technology based on more than 30 years of experience with bench grinders

Specially designed Spindle

The DWX-42w Plus features a new, heavy-duty spindle and requires only 0.22 MPa of compressed air, eliminating the need for a separate air compressor. There are also multiple milling techniques to choose from to speed up production for all dental applications. Produce up to three dental restorations simultaneously for faster production, or add the multi-pin holder to mill up to six dental implants at once. Use the device's multiple functions to produce high-quality crowns, veneers, small bridges, inlays, onlays and screw-retained implants.

Increase Your milling capacity

With the 6-pin adapter

Double your unattended milling capacity from 3 to 6 jobs with the ZV-42W 6-pin adapter, designed for the DWX-42W Plus and 14 mm or smaller pin blocks. Mill up to 6 pin-shaped blocks together with this easy-to-install accessory, which is compatible with the latest version of the Millbox and hyperDENT CAM software* and can be used together with the AK-1 Abutment Kitcan be used. The 6-pin adapter is another accessory for the DWX-42W Plus wet milling machine to increase production and profitability.

*Compatible with Millbox for DGSHAPE Wet Milling v4.2.x (2020) or higher and hyperDENT Service Pack 1 for v9.1 or higher.

| Machinable materials* | Glass ceramic, composite resin | |

| Loadable workpiece shape | Pen type | Max. 40 mm (W) × 20 mm (D) × 20 mm (H) (1.5″ × 0.8″ × 0.8″) |

| Operating speed | XYZ axes | 6-1800 mm/min (0.24-70.9″/min) |

| Spindle speed | 15000-60000 1/min | |

| Rotation axis movement angle | A | ±360° |

| Number of integrated grinding wheels | 6. | |

| Mountable grinding wheel | Shaft diameter | 3 mm, special grinding tools |

| Required compressor specification (oil-free, with dryer) |

0.3 MPa or higher | |

| Air capacity | 39 l/min or higher | |

| Interface | USB or Ethernet (10 BASE-T/100 BASE-TX auto-switching) | |

| Control command set | RML-1, NC code | |

| Energy supply | AC 100-240 V ± 10 %, 50/60 Hz (overvoltage category: II, IEC 60664-1), 2.1 A | |

| Power consumption | About 190 W | |

| Operating noise | In operation | 70 dB (A) or less (between cutting operations) |

| In standby | 48 dB (A) or less | |

| External dimensions | 482 mm (W) × 560 mm (D) × 600 mm (H) (19″ × 22″ × 23.6″) | |

| weight | 61 kg | |

| Installation environment | Use in closed rooms up to 2000 m above sea level, temperature: 5-28 °C (41-82 °F), humidity: 35-80 % rel. (no condensation), pollution degree: 2 (according to IEC 60664-1), temporary overvoltage: 1440 V, permanent overvoltage: 490 V | |

| Scope of delivery | Power cord, USB cable, manuals, DGSHAPE software package on CD, template for automatic correction, grinding tools, hexagon screwdriver, collet maintenance kit, etc. | |

Additional information

| Weight | 67000 g |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.