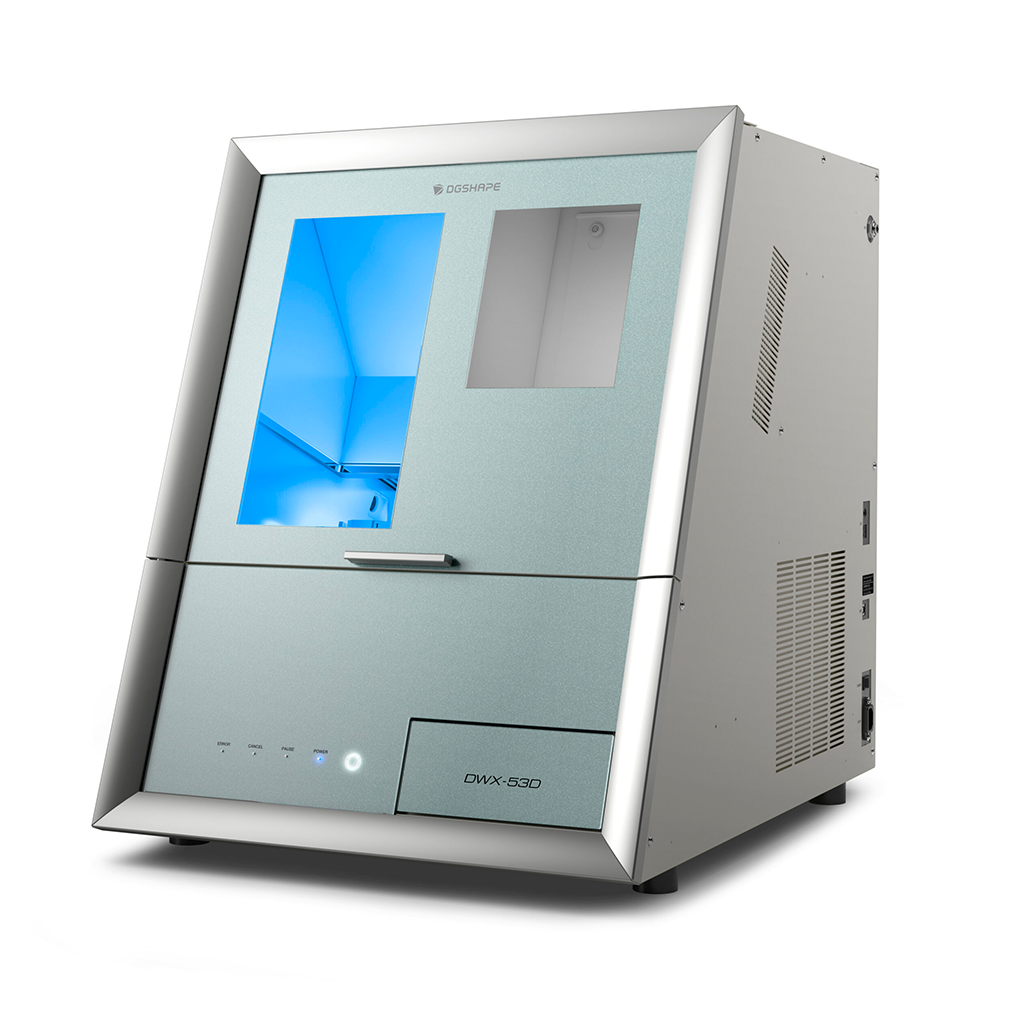

Description

Excellent milling quality

The undercutting of dentures and anterior teeth is reduced by increasing the inclination of the B-axis from 30 degrees on the DWX-52D to 35 degrees on the DWX-53D. This ensures that more detail can be achieved when producing a full-jaw construction. The spindle also has a significantly higher gripping force.

Higher productivity thanks to reinforced frame structure

Thanks to the faster motors and the more rigid structure of the machine, time savings of 30 - 48 % can be achieved. This also ensures that the surfaces of the end products are more homogeneous. It is also possible to manually adjust or improve the calibration of the machine by milling certain geometric shapes.

Automatic cleaning

The cleaning system blows off dust with a high-pressure air stream, and removes 95%. This new function reduces the time otherwise required to manually remove zirconium dust.

Integrated camera

The integrated camera connected to DGSHAPE Insights provides live images and updates, allowing users to monitor the status of their machine and production progress from anywhere and at any time using a smartphone, tablet or PC. These updates also support timely maintenance and servicing.

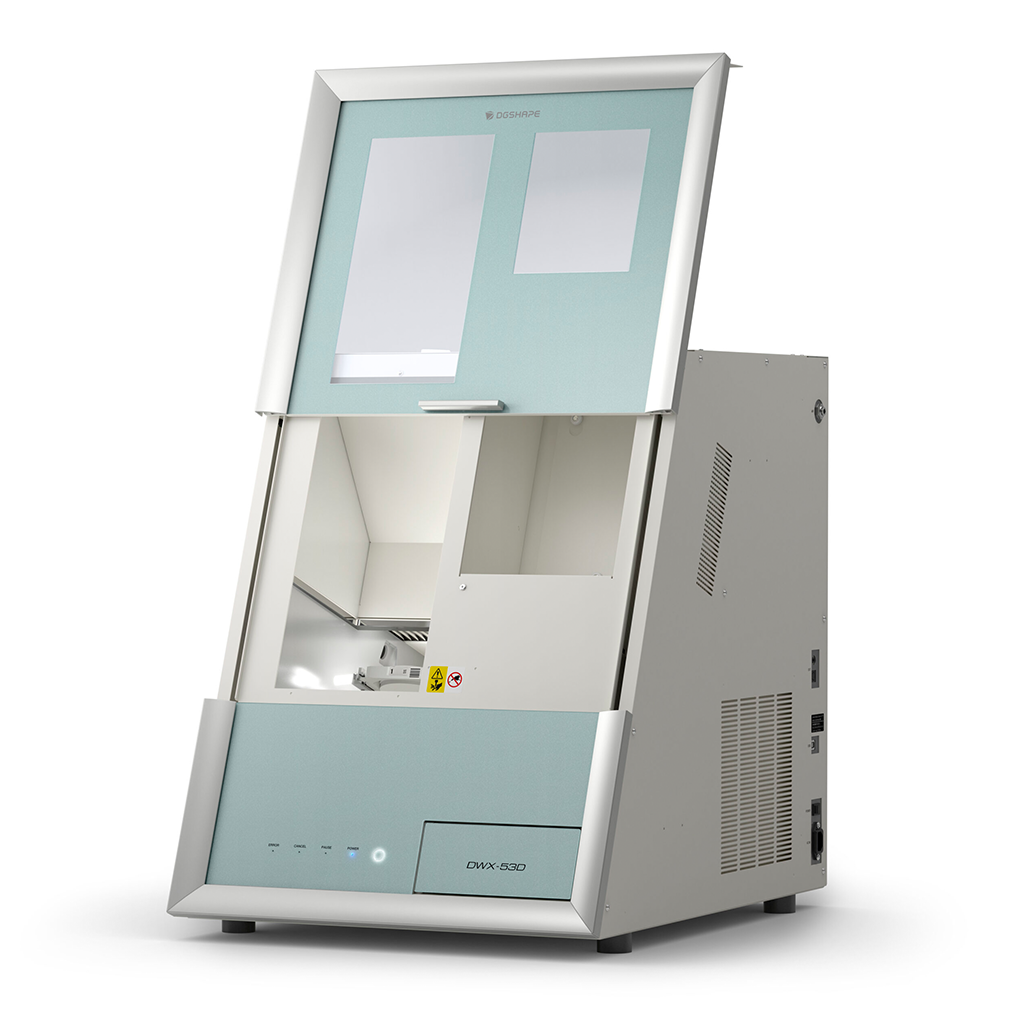

UP And Down sliding door

The door has a handle at the bottom and is opened by sliding it upwards. This method reduces the amount of dust that escapes from the machine.

Removing and locking the adapter

The removable and lockable adapter parts have been further developed from the DWX-52D. The fastening knob is large and easy to grip to enable one-handed attachment/removal and one-handed locking

Temperature equalization and control

A milling machine is a composite of many metal parts, the parts themselves expand and contract with the temperature. The integrated temperature sensor warns the user if fluctuations in the ambient temperature could affect the milling accuracy.

Overview

Millable material

Millable applications

Weight and dimensions

Loadable workpiece shape

Speed and axis movement angle

Attachable cutters

Information on the service

Power consumption: Approx. 170 W

Further technical data:

Control command set: RML-1, NC code

Compatible compressed air: 0.4 MPa

Spindle motor: Brushless DC motor

Spindle motor speed: 6,000 to 30,000 rpm

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.