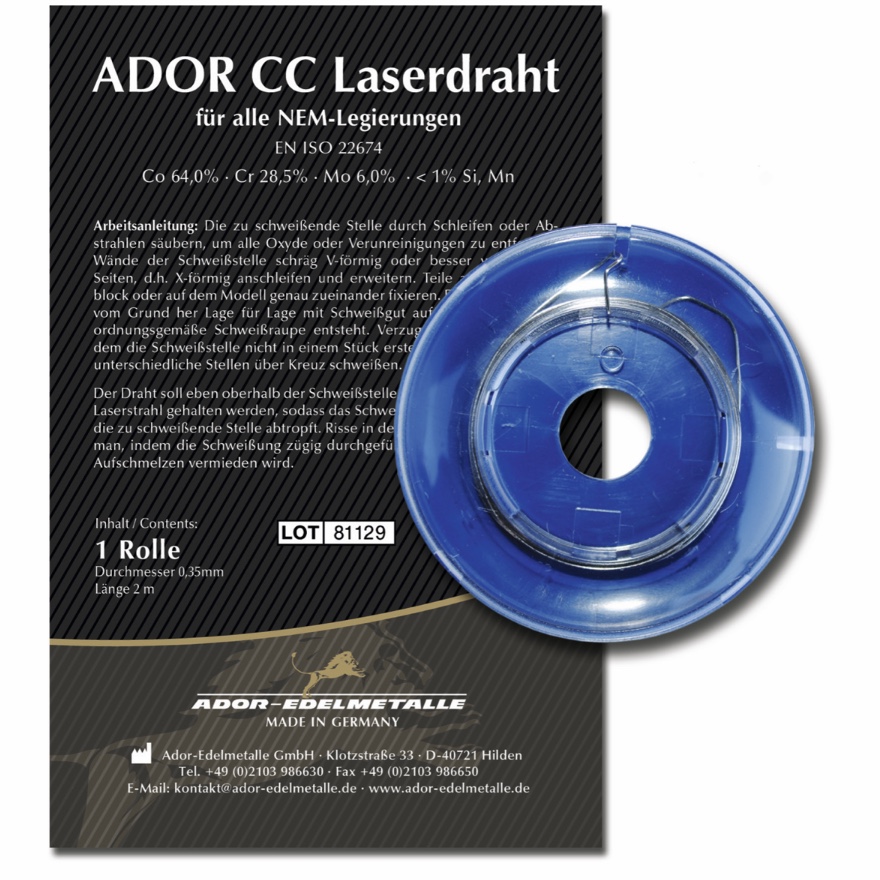

ADORBOND CC NEM Laser Wire

Stangen – 200mm, Packung á 2m

Suitable for all non-precious alloys.

49,90 € – 54,90 €Price range: 49,90 € through 54,90 € excl. VAT

| Title | Menge | Preis/Stück |

|---|---|---|

| NEM Lote und Laserdrähte | 5 - 9 | 5% 47,41 € |

| NEM Lote und Laserdrähte | 10 - 24 | 10% 44,91 € |

| NEM Lote und Laserdrähte | 25 - 49 | 15% 42,42 € |

| NEM Lote und Laserdrähte | 50 - 99 | 20% 39,92 € |

Description

Laser wire for our non-precious alloys. Available in thickness of 0.50 mm and 0.35 mm.

Gebrauchsanweisung-CC-Laserdraht-0,35.pdf

Gebrauchsanweisung-CC-Laserdraht-0,5.pdf

Composition:

Co 65.2 % | Cr 27.7 % | Mo 5.8 % | Fe, Si, Mn, N <1%

Processing recommendation

Clean the area to be welded by sanding or sandblasting to remove any oxides or contaminants. Walls of the welding point obliquely V-shaped or better obliquely from both sides, i.e. X-shaped, grind and expand.

Just above the welding point, the wire should only be held with the tip in the laser beam, so that the weld metal drips point by point onto the area to be welded. Cracks are avoided in the welding zone by quickly performing the weld and avoiding multiple melting.

Safety instructions

Metal dust is harmful to your health. Grinding and polishing with suction.Laser welding in a closed chamber with the deduction of welding fumes. Hypersensitivity to the alloy components should be taken into account. In case of suspected intolerance with certain solder components, the product should not be used.

Additional information

| Weight | 10 g |

|---|---|

| Modification | Ø 0.35 mm, Ø 0.50 mm |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.